The AED 5 Million Mistake: A Penthouse Diary of Regulatory Hell in Dubai

You Don’t Know What You Don’t Know

The quickest way to burn AED 5 million in interior design Dubai isn’t a bad contractor; it’s a single, misunderstood line item in the DCD’s fire code that your superstar designer from London never thought to check. I’ve seen it happen. A beautiful penthouse, panoramic views of the Burj Khalifa, a client with a blank check, and a design that was dead on arrival. They just didn’t know it yet. Everyone was focused on the Italian marble and the German fixtures, celebrating a concept that was physically impossible to build under UAE law. It’s a classic story. A tragedy in three acts: ambition, bureaucracy, and finally, bitter compromise.

Month 1-2: The Honeymoon Phase & The Ticking Time Bomb

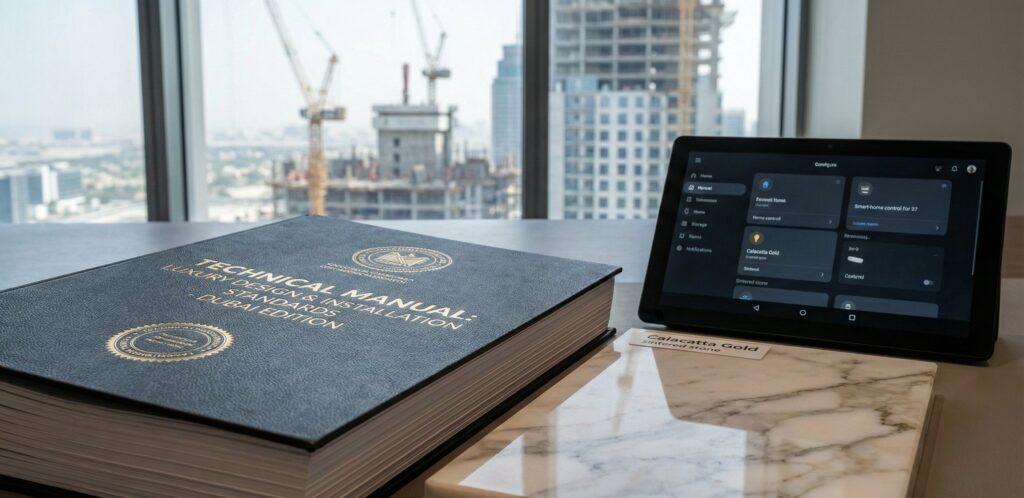

It all starts beautifully. Always does. The client, a family office representative, signs off on a breathtaking render package from a hotshot design firm—the kind you see winning awards, maybe a spin-off from Pallavi Dean or Bishop Design. The centerpiece is a floor-to-ceiling, seamless, book-matched feature wall of Calacatta Gold marble, intended for the main majlis. It’s a 10-meter-long monolith of stone, a statement piece. The budget is north of AED 15 million for the full fit-out. The initial material samples arrive from Italy, the smart home integration plan from the Crestron guys is a work of art, promising one-touch control of everything. The client is ecstatic. The designer is lauded as a genius. They are all celebrating. Honestly, I’m just looking at the spec sheet for the marble’s backing panel and the proposed adhesive system and I can already feel the headache starting. The contractor won’t tell you that the European EN 13501-1 fire classification on the supplier’s datasheet means absolutely nothing to a Dubai Civil Defence inspector. Zero. The project manager, meanwhile, is busy coordinating container shipments to Jebel Ali Port. He’s thinking about logistics. He’s not thinking about the composition of epoxy resin.

Month 3-4: The First Papercut from Dubai Municipality (DM)

The first submission package goes to Dubai Municipality. This isn’t DCD yet, just DM. This is for the architectural and structural NOCs. The plans come back with comments, as expected. It’s never a clean approval. The DM plan checker, working strictly from the Dubai Building Code, has flagged the weight of the marble feature wall. It’s a two-ton monster. The original structural drawings for the tower never accounted for a point load like this on a non-load-bearing partition. So, now we need a redesign. Steel reinforcement needs to be added to the partition and anchored to the main slab, which requires a new structural calculation, a third-party engineering review, and a resubmission. This adds three weeks and AED 80,000 in engineering fees. It’s an annoyance, not a disaster. But it’s the first domino. The new steelwork forces a change in the MEP drawings. The AC ducts have to be re-routed, which lowers the ceiling height by 10cm in one corner, which in turn messes with the recessed lighting plan from the German supplier. The Lutron smart home integrators are now screaming because their pre-planned cable pathways inside that wall are blocked by steel. See how it starts? It’s never one thing. It’s the cascade. The project manager assures the client it’s ‘standard procedure’. It’s not.

Month 5-6: The DCD Haymaker That Kills the Dream

Here’s where it gets ugly. After clearing the DM hurdles, the full construction package, including material specifications and fire-rated assembly details, goes to the Dubai Civil Defence portal. Two weeks of silence. Then, rejection. A single line in an email: ‘Feature wall assembly in main living area does not meet fire classification as per UAE Fire and Life Safety Code of Practice. Provide DCD-approved third-party certification for all components.’ The client is confused. ‘But the marble is a rock! It can’t burn!’ they say. The reality is, DCD doesn’t care about the rock. They care about what’s behind it. The imported Italian marble slabs were ultra-thin, reinforced with a proprietary fiberglass and epoxy-resin backing to prevent cracking during transit. The specified adhesive was a high-strength, two-part epoxy. Both the backing and the adhesive are combustible. They release toxic smoke and contribute to fire propagation, a catastrophic failure under Chapter 3 of the UAE Code. The supplier’s European test certificates? Worthless. DCD only accepts reports from approved UAE-based laboratories. Getting a new material tested can take three to four months and has no guarantee of passing. The multi-million dirham shipment of bespoke marble is now stuck in a Jebel Ali Port warehouse, racking up storage fees. This is the kill shot. A firm that specializes in this market, like Antonovich Design, builds their entire design library around pre-approved materials and assemblies for this exact reason. They know the DCD playbook. The award-winning international designer did not.

Month 7-8: The Slaughterhouse of ‘Value Engineering’

The project is now three months behind schedule and bleeding money. The client is furious. The designer is defensive. The only path forward is to butcher the original design, a process they politely call ‘value engineering’. The two-ton marble wall is dead. It’s replaced with DCD-approved, fire-rated GRC (Glass Reinforced Concrete) panels, finished with a ‘marble effect’ paint. It looks as good as it sounds. The seamless, monolithic dream is now a grid of panels with visible joint lines. The entire character of the space is gone. Let’s be real, this is where you see the real cost of a cheap initial quote versus a realistic one in a high-stakes residential fit-out. The contractor won’t tell you that cutting corners on early-stage consultancy and code compliance is the most expensive decision you can make. It just shows up later on the bill.

| Metric/Feature | The Standard ‘Dream Design’ Quote | The Antonovich Design Reality |

|---|---|---|

| Feature Wall Material | Book-matched Italian Calacatta Gold slabs with non-compliant resin backing. | Sintered stone or large-format porcelain with full DCD-approved assembly certification from day one. |

| Approval Timeline (DCD) | Estimated 2 weeks. Actual: 3+ months, including rejection and redesign. | 4 weeks, built into the project plan. Pre-vetted materials mean first-time approval is likely. |

| Hidden Costs | AED 500k+ in redesign fees, material testing, Jebel Ali storage, and delay penalties. | Higher initial design & compliance fee (approx. AED 150k), but avoids catastrophic downstream costs. |

| Final Aesthetic | Drastic compromise. Painted GRC panels instead of real marble. Client is unhappy. | The delivered project matches the approved render, maintaining design integrity. |

Month 9-12: Death by a Thousand Bureaucratic Cuts

You’d think the pain is over. You’d be wrong. The contractor, now working with the butchered and approved drawings, finally reaches the finish line and applies for the Building Completion Certificate (BCC) from the master developer and the relevant authority, let’s say it’s the Dubai Development Authority (DDA) for this project. But the DDA system cross-references all submitted documents. It flags an inconsistency: the final DCD-approved drawings for the GRC wall don’t perfectly match the structural drawings approved by DM six months ago because a minor electrical conduit was moved. Another hold is placed on the account. Another two weeks lost arguing over an insignificant change. Then DEWA conducts its final inspection and finds that the new GRC panels have slightly altered the placement of a socket, which is now 5cm too close to a water source, according to their latest circular. More revisions. More delays. The project is finally handed over six months late, AED 5 million over the original budget (when you factor in lost rent, extra fees, and wasted materials), and the client hates the GRC wall. They stare at the compromised masterpiece and all they feel is resentment. The designer has already moved on to their next award-winning concept.

The Hidden Risk Checklist That No One Gives You

- Material Provenance & Local Certification: Does your specified material have a valid UAE test certificate from a DCD-approved lab?

- Is the backing material certified?

- Is the adhesive certified?

- Is the entire assembly (substrate + adhesive + material) certified as a system?

- Inter-Agency Drawing Consistency: Are your DM, DCD, DEWA, and DDA drawings 100% identical?

- A 10cm shift in a wall on one drawing that isn’t reflected on all others will trigger a system-wide rejection.

- Contractor’s Authority Liaison: Does your contractor have a dedicated, experienced PRO who has a working relationship with inspectors, or just a junior employee who knows how to upload files to a portal?

- FIDIC Contract Clauses: Are your delay penalties and liabilities for regulatory rejection clearly defined in your FIDIC contract? Or is it a vague clause that leaves you exposed?

Questions You’re Probably Asking Yourself

Why can’t I just use materials with European or American fire-rating certificates for DCD?

Because the UAE Fire and Life Safety Code is sovereign. DCD mandates local testing to account for regional climate conditions, construction methods, and their own specific risk assessments. A certificate from a lab in Germany is considered supporting documentation at best, not proof of compliance. In the Dubai market, this means local testing is non-negotiable for any new or complex material assembly.

What’s the real difference between a Dubai Municipality (DM) permit and a DCD approval?

They look at completely different things. DM is primarily concerned with the building’s bones: structural integrity, zoning laws, architectural compliance with the Dubai Building Code, and basic MEP layouts. DCD is obsessed with one thing: fire and life safety. They scrutinize material combustibility, smoke toxicity, escape routes, fire suppression systems, and alarm integrations. You can have a structurally perfect design that DM loves, but if it’s made of flammable materials, DCD will kill it instantly.

How does a FIDIC contract protect me from these kinds of regulatory delays?

It depends entirely on how it’s written. A standard FIDIC (International Federation of Consulting Engineers) contract might put the onus of regulatory compliance on the contractor. But if the delay is caused by a fundamental flaw in the *design* (i.e., specifying a non-compliant material), the liability can shift back to the designer or, if the contract is weak, to you, the client. A well-drafted contract will include specific clauses that assign liability for delays caused by non-compliant design specifications from the outset.